Updraft Wind Turbine:

background

Wind

power accounts for about 8

percent of the electricity produced in North

America. Some 50,000 + large wind turbines

crank out power throughout the continent.

These massive wind turbines, up to 100 meters

tall, capture energy in the wind and convert

it electricity that people can use to run

dishwashers, air conditioning and lights. That

8 percent may not sound like much until we

realize that the wind power is just catching

on. Huge new wind farms accounting for

thousands more megawatts of capacity are in

the development.

Trouble

in

the industry

Conventional

wind

turbines with large blades are destructive

to communities and local environments.

Animal habitats are disrupted and wildlife

is driven from the area. Noise and

vibrations cause human health problems. Home

values and real estate prices are reduced.

How does it work

In a conventional design,

large diameter blades, turbine-generator and

other heavy equipment are mounted on top of

the tower. Our design brings the small

diameter turbine-generator back to the ground

level, eliminating many shortcomings of the

conventional wind turbines. The only elevated

portion in our design is a balloon based

intake, which does not have moving parts.

Balloon allows the intake to be floated to

higher elevations. That flexibility does not

exist with a rigid tower.

The balloon lifted intake,

made of light materials, incorporates a

venturi system interconnected to the ground

based wind turbine by a lightweight pipe.

Wind, with a help of the venturi effect

induces air updraft to power the turbine

generator. In addition, a natural updraft

based on the buoyancy due to pressure and

temperature difference between the ground

level and the balloon helps to produce energy,

even in the absence of the wind.

To sum up, a balloon based WindUpdraft

system makes conversion of wind energy to

electrical power safer and more economical.

Background

of the invention (Canadian Patent 2,808,001)

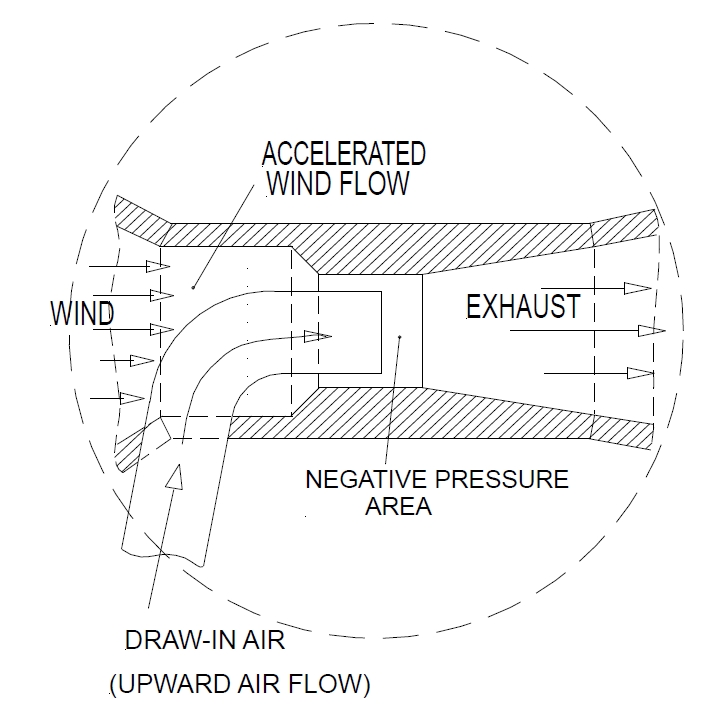

The purpose of the system is

to collect energy generated by airflow from

the wind, extract it and convert it to

electricity. A lighter than air helium filled

balloon is used to lift air intake portion of

a wind energy conversion system in order to

harness the wind energy. The turbine and the

generator are mounted on the ground. The

intake nozzle assembly is configured to

receive and to accelerate wind. The

accelerated wind creates low air pressure area

in the venturi piping downstream of the

balloon. This point of suction is where a

lightweight reinforced piping connects to

allow the air from the ground to be drawn in

the upward direction. The resulting air

movement spins the ground mounted turbine and

the generator. The mounting of the generating

system on the ground allows economical

maintenance due to relatively easy access.

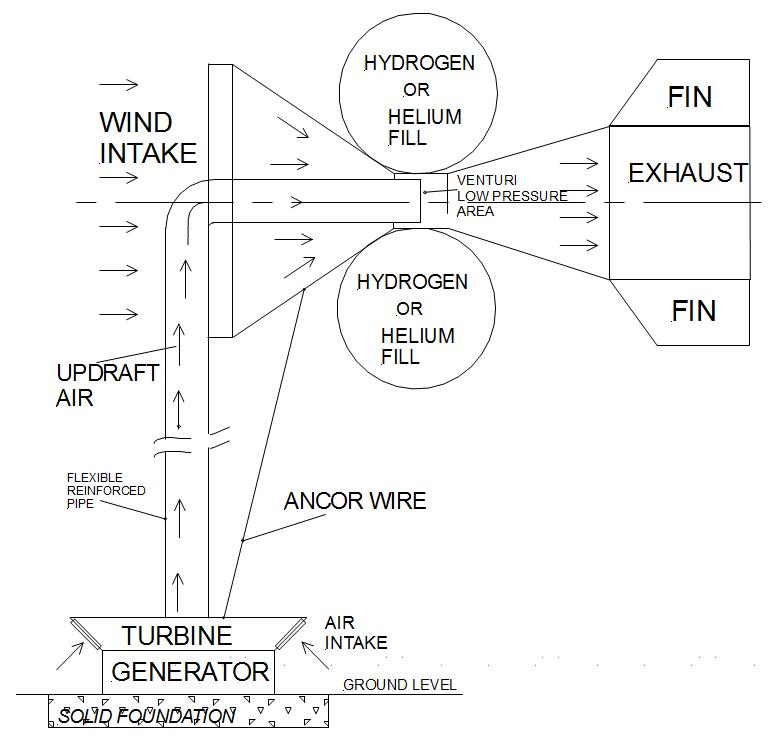

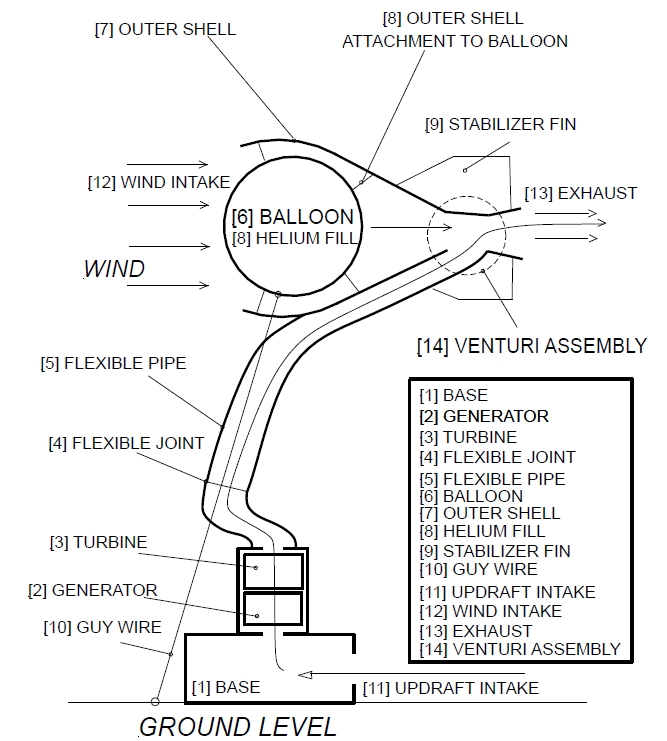

MAIN COMPONENTS OF THE SYSTEM

The

system

shown on the drawings is the proprietary system

being registered in Canada for patent

protection, and comprises of the following main

components (Fig.1):

Base

Generator

Turbine

Flexible tube

Outer shell

Balloon

Venturi piping assembly

(Fig.2)

Helium filled balloon

The wind enters the outer shell of the wind

concentrator mounted on the helium balloon,

(Fig.1). It is shaped similarly as the intake of

a jet engine. Due to the laws of the physics the

wind speed will increase as the pipe diameter

decreases. The increased air speed creates area

of lower air pressure due to the venture effect.

This becomes our connection point to the

vertical pipe which leads to the turbine and the

generator mounted on the ground level. The lower

air pressure causes a high velocity air to flow

up in the pipe from ground intake to the

balloon. This high velocity air movement causes

the turbine to spin. A generator, connected to

the turbine converts the mechanical spinning

motion of the turbine into electricity.

A

high strength cable system extends from the

ground to the balloon to ensure the mechanical

integrity under the worst weather conditions.

The system turns always towards the wind with

the help of the stabilizer fins.

The initial operating altitude of the system will be approximately 10 to 20 meters, subject of the local bylaws. In rural areas the air collection system can be elevated to 100 meters or beyond.

Fig. 1. WIND ENERGY CONVERSION SYSTEM Canadian Patent CA2808001

Fig.

2. VENTURI

ASSEMBLY – single stage shown for clarity

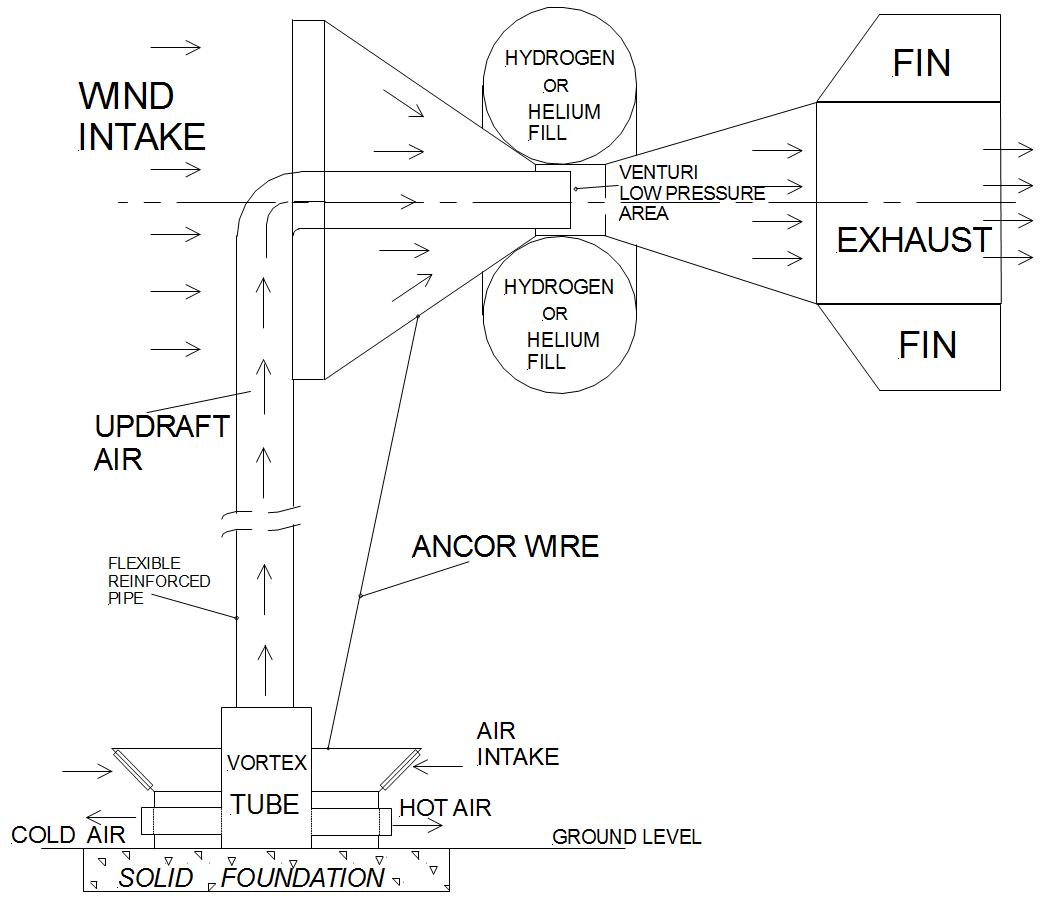

Additional Benefits: Heating and Cooling system

uWIN lands itself for a direct production of heating or cooling air, using vortex (Ranque-Hilsch) tubes. The updraft airflow in the pipe (Fig.3) passes through large vortex tube, where spinning air creates hot and cold air streams.

Conventional wind turbines

need to produce electricity first and then feed

electric power to heating or air cooling system.

Fig. 3. VORTEX TUBE

APPLICATION FOR HEATING OR COOLING

Is this a

wildlife-friendly wind

turbine?

See attached article for

more details.